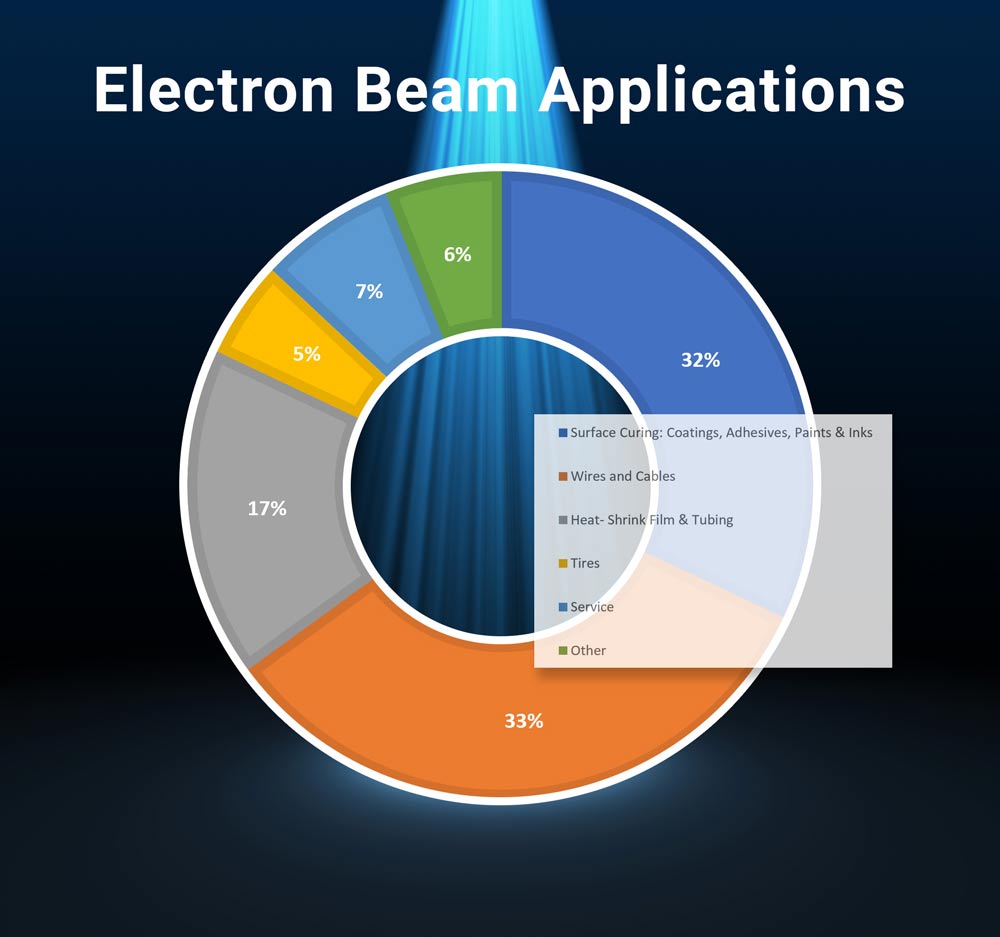

Electron Beam (EB) does a lot of things, but perhaps the most significant one is the ability to break bonds of polymers. When chemical bonds are broken, they produce free radicals (unpaired valence electrons), which are the drivers of free-radical chemical reactions. These are the basis of the majority of present-day commercial EB applications. An electron beam can start a range of reactions by exposing a material to accelerated electrons. These reactions include cross-linking, polymerization, chain scission, and grafting. Adopting these reactions to commercial applications has resulted in the technology penetrating a diverse range of markets.

Electron Beam Commercial Success with Cross-Linking Polymers

EB’s first commercial applications appeared in the late 1950’s and early 1960’s when plastic films were cross-linked.

Cross-linking is accomplished when linear or branched polymer chains are chemically bonded into a cross-linked network. EB produces this effect by breaking bonds inside a polymer, leaving these broken chains able to create a network across and with adjacent chains. Cross-linking is straightforward with no other chemical involvement. The process of bonding polymer chains together leads to improvements in film properties such as tensile strength, heat and solvent resistance, as well as the ability to shrink. These property improvements, in many film applications, allow a reduction in film gauge to accomplish the same performance result. EB cross-linking is effectively and broadly used in the production of shrink films, vacuum skin packaging, insulation for cables, tires, a variety of tapes, and cold seal adhesives.

Polymerization is a process of reacting prepolymer monomers and oligomers together in a chemical reaction that forms polymer chains, or cross-linked three-dimensional networks. In practice, this reaction initiated by EB exposure, produces robust coatings, inks, and adhesives that exhibit low to no odor and low migration. EB polymerization occurs almost instantaneously, without an initiator or the use of a solvent. Electron penetration is affected by the density of a material, while clarity is not a factor.

EB is therefore effective in curing opaque coatings, inks, and adhesives, and will cure through metalized laminate substrates. Coating and print applications of EB polymerization are found to be applied to paper, paperboard, film, wood, laminate, and metal materials. End products are found across rigid and flexible packaging, including ice cream containers, beverage cartons, silicone release substrates, and architectural materials, etc.

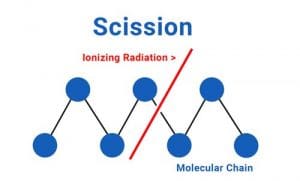

Scission is Breaking Chemical Bonds

Scission is defined as the state of cutting or being cut. In chemistry, it’s the breakage of a chemical bond, especially one in a long chain molecule, so that two smaller chains result. Cross-linking and scission always happen at the same time. The one that dominates is dependent on the polymer involved. An example of chain scission is sterilization, where a natural polymer, the DNA of microorganisms, under EB exposure scissions, destroys the microorganisms. EB chain scission is being applied in the production of aseptic packaging, and the sterilization of certain food products, including, control of salmonella in meats and seafood, disinfection of herbs, spices, garlic, and potatoes, insect disinfection in cereals, nuts, milled products, dried fruits, sprouting inhibition in bulbs and root tubers, etc. EB chain scission is also being used in the recycling of PTFE by degrading it into a usable powder slip agent, with an application as an additive in inks, coatings, and lubricants.

Scission is defined as the state of cutting or being cut. In chemistry, it’s the breakage of a chemical bond, especially one in a long chain molecule, so that two smaller chains result. Cross-linking and scission always happen at the same time. The one that dominates is dependent on the polymer involved. An example of chain scission is sterilization, where a natural polymer, the DNA of microorganisms, under EB exposure scissions, destroys the microorganisms. EB chain scission is being applied in the production of aseptic packaging, and the sterilization of certain food products, including, control of salmonella in meats and seafood, disinfection of herbs, spices, garlic, and potatoes, insect disinfection in cereals, nuts, milled products, dried fruits, sprouting inhibition in bulbs and root tubers, etc. EB chain scission is also being used in the recycling of PTFE by degrading it into a usable powder slip agent, with an application as an additive in inks, coatings, and lubricants.

Grafting Polymerization

Grafting results when a polymer and a prepolymer receive EB exposure at the same time. Accelerated electrons break internal polymer bonds creating reaction sites allowing the prepolymer to bond and polymerize. Surface modification has been the largest application for grafting. Included are functional fabrics providing high wash durability, water repellence or absorption, polymer membranes, thermo-responsive surfaces, battery separators, and deodorizing-/anti-bacterial functionality.

Electron Beam Lithography

In other areas, EB has found applications in delicate metal cutting, micromachining, and EB lithography. EB lithography is a direct writing method using accelerated electrons to high-resolution pattern sub-nm features into an electron-sensitive resist. It is used in photomask making and semi-conduction production. EB litho technology is key to the production of microelectronics.

It’s said that much of EB’s huge potential remains to be exploited. The pace is likely to pick up as today’s environmentally conscious society is inspired to save the planet. Important to this, EB is a green technology based on its low energy operating consumption, and it is being a solvent-free process. New uses are emerging constantly as EB’s advantages are recognized.

�鶹��ý���� offers EB coatings that provide High Gloss, Matte, & Semi-Gloss/Satin finishes, with some that are Recoatable, Stampable, Glueable, and Imprintable. Contact �鶹��ý���� Technical experts if you require a UV/EB coating with enhanced performance properties for a demanding application. �鶹��ý����’s business is the development and formulation of Aqueous, energy-curing Ultraviolet (UV), and Electron Beam (EB) specialty coatings and adhesives.