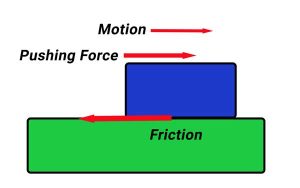

Opposing, as they are, friction and slip are key to much of what functions on Earth. Without friction we would not be able to walk, we would slip, and slide with little control. Driving relies on tires to maintain a grip on pavement giving us vehicle control through friction.

Brakes control our ability to stop using the friction between brake pads and discs. Even ice skating surprisingly relies on sharp skate blades developing a frictional grip with the slippery ice surface. Meanwhile, slip or low sliding friction, allows us to defy friction to move effortlessly as in skiing or sledding downhill on snow and ice. Simply put, friction is the force that holds back a sliding object.

Definitions can give us a quick guide to these functional properties.

FRICTION: is the resistance to the movement of one body with another while in contact.

The amount of friction depends on the type of contact surfaces, and the amount of force (usually gravity) pressing the surfaces together. The surface area of the contact surfaces does not matter. Four types of friction are: static, sliding, rolling and fluid. There are two main types of friction, static friction and kinetic friction. Static friction is always greater than kinetic or sliding friction. This is because more forces keep an object stationary than there are resisting an object that is moving.

The amount of friction depends on the type of contact surfaces, and the amount of force (usually gravity) pressing the surfaces together. The surface area of the contact surfaces does not matter. Four types of friction are: static, sliding, rolling and fluid. There are two main types of friction, static friction and kinetic friction. Static friction is always greater than kinetic or sliding friction. This is because more forces keep an object stationary than there are resisting an object that is moving.

STATIC FRICTION: exists when two surfaces are at rest and not moving in relation to one another. Picture the force needed to lift or move a heavy carton.

KINETIC FRICTION: exists when two surfaces are in motion relative to one another, like a thrown piece of mail sliding to a stop on a desk top.

SLIDING FRICTION OR SLIP: defines the lubricity of two surfaces sliding in contact with one another, like a sled sliding on snow or ice. It works to slow or stop an object in motion. Low friction occurs when smooth surfaces in contact easily slide.

FLUID FRICTION: exists in liquids where friction is the resistance between moving layers of a fluid, known as viscosity.

ANTI-SKID: describes the increasing of friction, and the raising of COF of an object (a package) to make its surface less slippery.

COF: Coefficient of Friction or COF is the ratio of the frictional force and the amount of force pressing two surfaces together. The coefficient is a measure of the resistance of the one surface to slide over the other. COF is based on the roughness of materials contacting one another, like concrete on concrete with a very high coefficient of friction, or Teflon on Teflon with a very low COF. Friction can be reduced by polishing a surface to reduce roughness, lubricating the interface between surfaces, using bearings, and streamlining.

MEASURING COF:

The most accurate, precise, and expensive devices are horizontal sled designs, either stationary sled with moving plane, or moving sled with stationary plane. Less expensive are inclined plane devices, either motorized or manual.

Consider the horizontal sled COF test design consisting of a base mounted smooth plane and a movable sled attached to a spring or strain gage. Conditioned test material is attached to both the sled and the plane creating surface contact when the sled is placed on the plane. In testing, the driving mechanism of the sled is started, which exerts a horizontal frictional force on the surfaces of the test material in contact.

When the pull on the sled is equal to or exceeds the static frictional force affecting the contact surfaces, movement takes place. The maximum gage reading observed is indicative of the force component of static COF. Next, as the surfaces continue to slide against one another the average gage reading is recorded. This reading is the force or kinetic force that is necessary for the sliding movement between the surfaces to continue. Recorded force data allows both static and kinetic COF to be calculated using formulas.

Static COF=As/B Kinetic COF=Ak/B

As=gage reading at initial movement

Ak=gage reading during uniform sliding

B=sled weight

Inclined plane COF test equipment consists of an inclined plane and a sled. Accuracy requires that the inclination of the plane must be able to be increased smoothly (from horizontal to at least 45 degrees). Movement must be capable of being read with at least 0.5 degrees of accuracy. Additionally, as with all COF testing equipment, the instrument must be accurately leveled. Initiating testing, the conditioned sample material is mounted to both the sled and the inclined plane. Once mounted, the inclined plane is elevated at a smooth, constant rate until the sled starts to move. At first sled movement, the inclination of the plane is stopped when an electro/mechanical switch is activated.

The angle reached by the inclined plane is recorded indicating the angle at which the movement of the sled first started. Static COF is equal to the tangent of the angle at which the material-mounted sled began to slide, μ=tan(Ɵ). Kinetic COF is found by starting the sled on the inclined plane at an angle just below the angle recorded for static COF. This is an estimating process knowing that the kinetic forces required will be somewhat less than the static force that initiated movement.

COF is dependent on surface smoothness therefore testing should be conducted both with the grain and cross-machine directions.

All test specimens must be conditioned following ASTM or other test methodology for temperature and humidity consistency. Sample material must be free of dust, lint, fingerprints, and any other foreign matter that could change surface characteristics. Multiple specimen (5) should be tested for each sample material with the results averaged for a final COF value. Standard deviation may also be calculated.

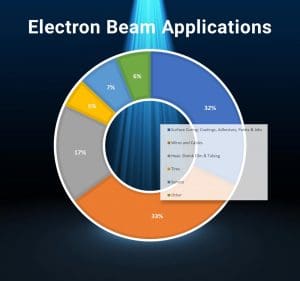

Contact �鶹��ý���� technical experts if you require either a coating with increased slip, or non-skid performance properties for an application. �鶹��ý����s’ business is the development and formulation of Aqueous, energy-curing Ultraviolet (UV), and Electron Beam (EB) specialty coatings and adhesives.